Hydrogen Iron Transport (HIT)

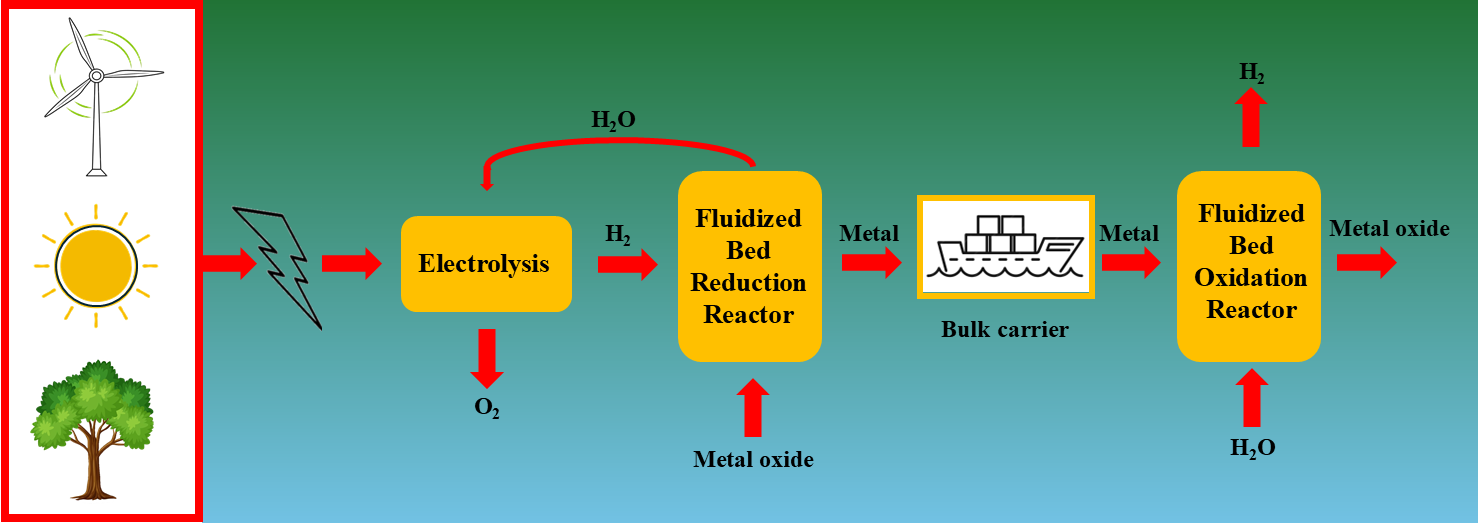

The HIT project investigates iron as a solid chemical energy carrier for large-scale hydrogen transport. Green hydrogen reduces natural iron ore, which can be transported over large distances and later oxidised to regenerate H₂ at its destination. This method offers a cost-efficient alternative to conventional methods.

This project is a collaboration between Italy and Germany, which connects two crucial hubs: Italy, strategically positioned in the Mediterranean, and Germany, centrally located in continental Europe.

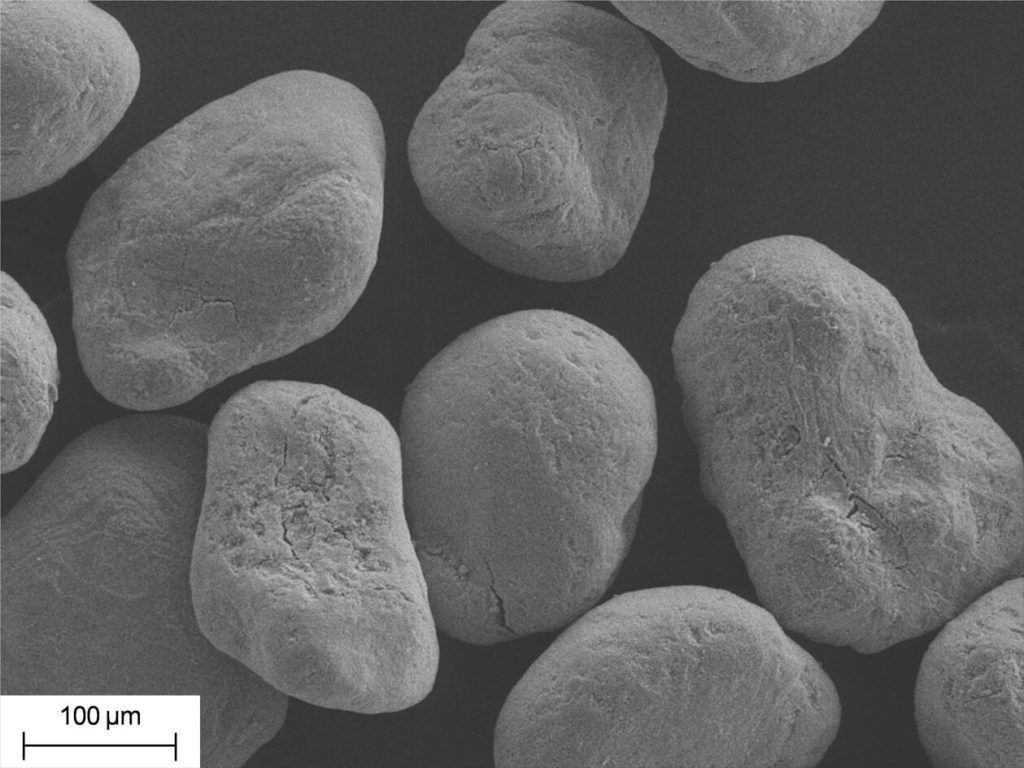

A detailed understanding of the oxidation and reduction processes of iron ore at the particle level is essential. Thermogravimetric experiments will provide reaction kinetics for both oxidation and reduction. A single-particle model will be developed to separate the influence of chemistry on the single-particle reaction rate from the heat and mass transfer processes. Multiple oxidation and reduction cycles must be conducted to assess potential reactivity losses.

Samples will be characterized by a wide range of analyses, including X-ray diffraction and scanning, electron microscopy, XRF, porosimetric analysis.

The reactor concept envisioned for this project is fluidized beds. Therefore, the behavior of multiple moving particles during oxidation and reduction must be examined. A small-scale fluidized bed test rig will be used to analyze the oxidation and reduction behavior under different gas compositions and temperatures. Multiple oxidation and reduction cycles will be carried out to assess scalability. Particle agglomeration and attrition will also be studied. The experiments will be used to validate a simulation model that incorporates a detailed single-particle model.

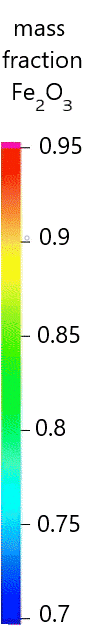

Simulation of the small-scale fluidized bed test rig (color indicates the oxidation degree of Fe to Fe2O3)

Scaling up to industrial size will involve two key steps: 1D process simulation (Modellica) and 3D simulations of the fluidized bed reactors (Barrcuda). The 1D simulations will provide the basic layout data for the reduction and oxidation plant, as well as the quantity structures of the plant’s components. This will also enable an initial cost structure for investments. The core component, the fluidized bed reactors, will be designed using 3D reactive fluid-particle simulations, allowing for detailed predictions of dimensions, operating regimes, and efficiencies.

Simulation of an industrial-scale fluidized bed reactor (color indicates particle volume fraction)

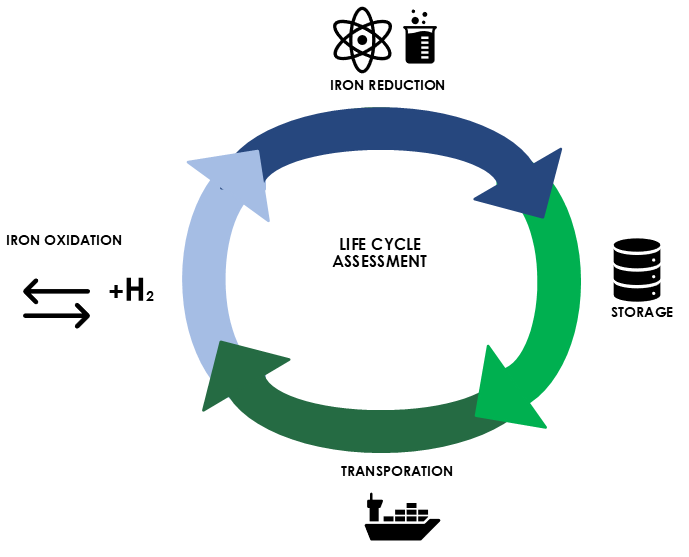

A comprehensive Life Cycle Assessment (LCA) and Techno-Economic Assessment (TEA) of the iron-based hydrogen transport and storage system proposed. The LCA will evaluate the environmental impacts associated with each stage of the system, from raw material extraction, transportation up to end-of-life disposal. The Life Cycle Costs (LCC) combined with the TEA will adopt the same system boundaries and functional units developed for the LCA to evaluate the costs of proposed innovative H2 supply chain. These will be compared with conventional routes of hydrogen transport (e.g., shipping in liquid form, through pipelines) as well as other alternative fuel on the market.